In the lifting and rigging industry, the swivel hoist ring has emerged as an essential component for enhancing safety and efficiency in load handling. According to a recent report by the Lifting Equipment Engineers Association (LEEA), the global market for lifting equipment, including swivel hoist rings, is projected to reach $8 billion by 2025, reflecting a compound annual growth rate of 4.5%. With the growing demand for versatile and safe lifting solutions, understanding how to choose the right swivel hoist ring becomes imperative for professionals in various sectors.

Industry expert Mark Johnson, a leading consultant in lifting technology, emphasizes the critical nature of making informed decisions when selecting hoisting gear. He states, "The correct swivel hoist ring can drastically improve operational efficiency and minimize the risk of accidents during heavy loading." This sentiment resonates within the industry, as improper equipment selection can lead to significant safety hazards and financial losses. Therefore, gaining insight into the different types of swivel hoist rings, their appropriate applications, and key selection criteria is necessary for any business looking to safeguard their operations while maximizing productivity.

Swivel hoist rings are essential components in material handling, designed to facilitate the safe and efficient lifting of heavy loads from various angles. These rings allow for a full rotation and pivoting of the load, making it easier to maneuver and position items precisely. Unlike traditional lifting points, swivel hoist rings can reduce the risk of load unbalance and enhance safety, as they effectively accommodate different lifting angles without compromise.

When selecting a swivel hoist ring, it's crucial to consider factors such as load capacity, the type of material being lifted, and the specific lifting environment. Always ensure that the chosen ring can handle the maximum weight you intend to lift and is compatible with the equipment being used. Additionally, inspecting the hoist ring regularly for wear and tear can prevent accidents during lifting operations.

**Tips**: Always refer to the manufacturer's guidelines for installation and maintenance practices. If you are unsure about the load requirements, consult a material handling professional to assist you in making an informed decision. Ensuring proper alignment and clearance around the load will also enhance safety during lifting operations.

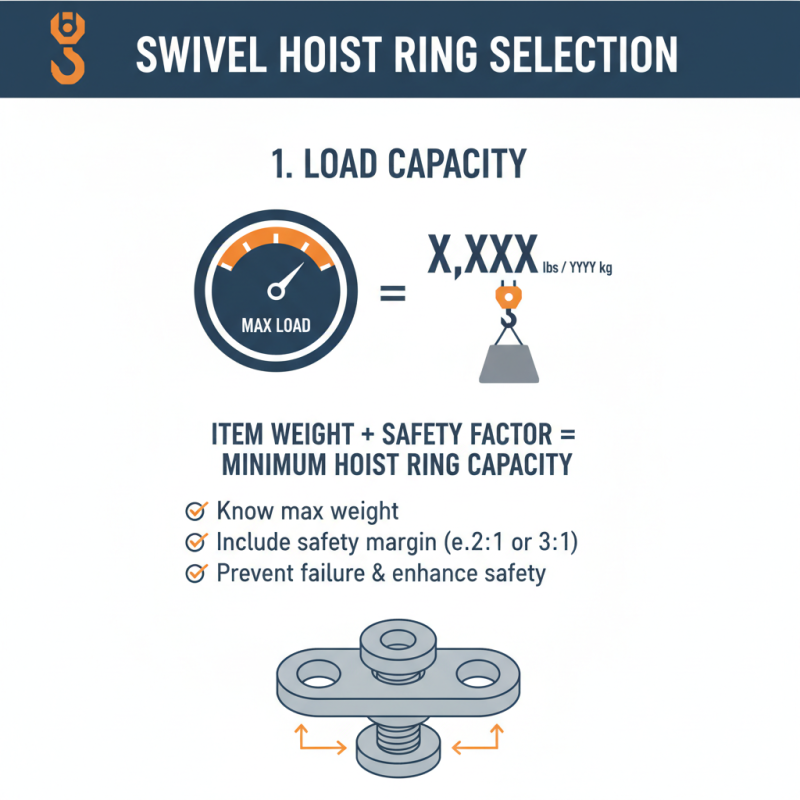

This bar chart illustrates the load capacities of different types of swivel hoist rings. Choosing the right hoist ring depends on the specific weight and handling requirements of your application. Ensure to select a ring that not only meets but exceeds your necessary load capacity for safety.

When selecting a swivel hoist ring, several key factors come into play to ensure optimal performance and safety. First and foremost, the load capacity is crucial. It’s essential to know the maximum weight the hoist ring will handle during operation. This capacity should not only accommodate the weight of the item being lifted but also include a safety factor to account for any unexpected stresses or loads during lifting. Choosing a ring with appropriate load ratings prevents failure and enhances safety in lifting applications.

Another important consideration is the material and finish of the swivel hoist ring. Different materials offer varying levels of strength, corrosion resistance, and durability. For instance, stainless steel rings provide excellent resistance to rust and are suitable for use in outdoor or marine environments, while carbon steel may be adequate for indoor settings. Additionally, the swivel mechanism’s design should be evaluated. A well-designed swivel allows for smooth operation and minimizes the risk of twisting or binding during lifts, which is vital for maintaining load stability. Ensuring that the hoist ring meets industry standards and certifications can further guarantee its reliability and longevity in various lifting scenarios.

When selecting the right swivel hoist ring for your needs, understanding load capacity ratings is crucial. The two primary terms you'll encounter are Safe Working Load (SWL) and Working Load Limit (WLL). SWL refers to the maximum load that can be safely lifted by the hoist ring, considering various factors, including the material, design, and intended usage. WLL, on the other hand, represents the maximum weight the hoist ring can handle in real-world applications, often accounting for safety factors specific to the equipment and environment. It's important to match these ratings with your lifting requirements to ensure safe and effective operations.

When choosing a hoist ring, consider the specific loads you will be handling and be sure to consult the manufacturer's specifications. For optimal safety, always select a hoist ring with a WLL that exceeds your maximum expected load. In addition, assess the orientation in which the hoist ring will be used, as this can affect its load capacity.

Tips: Regularly inspect your hoist rings for any signs of wear or damage before use, and always ensure that the load is evenly distributed to maintain stability. Consider consulting with industry professionals to select the right hoist ring that meets both your operational demands and safety standards.

| Ring Type | SWL (Safe Working Load) | WLL (Working Load Limit) | Material | Finish |

|---|---|---|---|---|

| Standard Swivel Hoist Ring | 5,000 lbs | 4,000 lbs | Steel | Zinc Plated |

| Heavy Duty Swivel Hoist Ring | 10,000 lbs | 8,000 lbs | Alloy Steel | Black Oxide |

| Lightweight Swivel Hoist Ring | 2,000 lbs | 1,600 lbs | Aluminum | Anodized |

| Corrosion Resistant Swivel Hoist Ring | 8,000 lbs | 6,500 lbs | Stainless Steel | Electropolished |

Swivel hoist rings are commonly used in lifting applications due to their versatility and ease of use. When selecting a swivel hoist ring, understanding the different materials and designs available is critical. Typically, these rings are fabricated from materials such as stainless steel, alloy steel, and aluminum. Stainless steel is preferred in environments where corrosion resistance is essential, while alloy steel provides superior strength for heavy-duty applications. Aluminum, being lightweight, is suitable for scenarios where minimizing weight is a priority while still maintaining sufficient lifting capacity.

In terms of design, swivel hoist rings can vary significantly, affecting their functionality. Some designs focus on allowing free rotation under load, which can prevent twisting of lifting slings and chains, thus enhancing safety. Other designs might feature locking mechanisms to ensure the ring stays in the desired position during lifting. Additionally, the load capacity and size of the hoist ring play vital roles, making it essential to match the product to the specific lifting requirements to ensure reliability and safety during operations. Understanding these factors helps users choose the appropriate swivel hoist ring for their unique needs.

When choosing a swivel hoist ring, understanding the standards and certifications pertaining to hoisting equipment is crucial for ensuring safety and reliability in lifting operations. Regulatory bodies such as the American Society of Mechanical Engineers (ASME) and the Occupational Safety and Health Administration (OSHA) have established guidelines and requirements which hoist rings must adhere to. Equipment that meets these standards is rigorously tested for load capacity and durability, reducing the risk of failure during operation. According to a report by the industrial safety organization, approximately 54% of workplace injuries are related to improper lifting and hoisting practices, underscoring the importance of selecting certified equipment.

Tips: Always check for certification labels and ensure that the swivel hoist ring complies with the relevant industry standards. Look for products that are tested for both static and dynamic loads, as this can significantly influence safety, especially in dynamic lifting environments.

Furthermore, ensure that the swivel hoist ring's specifications align with your intended application, considering factors such as load weight, angle of lift, and environmental conditions. Certified hoisting equipment provides reassurance that the product has been evaluated for quality and safety, minimizing operational risks. Regularly consulting industry reports and updates on safety standards can be beneficial in making informed decisions about hoisting equipment.

Tips: Stay updated on the latest safety regulations and certifications by attending industry seminars or subscribing to relevant publications; this proactive approach helps maintain compliance and enhances workplace safety.