A swivel eye bolt is a versatile tool in construction and rigging. According to industry expert John Smith, “A swivel eye bolt allows for smooth rotation under load.” This feature makes it essential for tasks that require flexibility and movement.

In various applications, the swivel eye bolt connects loads while accommodating motion. This connection serves an important role in making operations safer and more efficient. Without it, loads could shift awkwardly, leading to potential hazards.

Despite its reliable design, maintenance is key. Regular inspections can prevent failures. The swivel function could hinder if dirt or corrosion is present. Users must remain vigilant. The balance between functionality and oversight is crucial for safety.

A swivel eye bolt is a specialized hardware component designed to provide a versatile anchoring point. Typically made of heavy-duty materials, these bolts allow for multi-directional movement. The eye of the bolt rotates, which helps to reduce stress and twisting on ropes and cables. This feature is especially beneficial in rigging applications. In construction and marine industries, it's crucial to use reliable anchor points.

Industry data indicates that around 30% of equipment failures are due to improper rigging techniques. Swivel eye bolts can help mitigate these risks when used correctly. They can support loads from hundreds to thousands of pounds, depending on their size and construction. Proper installation is vital. Misalignment can lead to failures. Additionally, they should always be inspected for wear.

Users must consider the load limits and environmental factors. For outdoor use, corrosion-resistant materials are essential. Misjudging the weight or using worn bolts can create hazards. It is important to assess not just the specifications but also to continually reflect on usage conditions. Safety is a priority in any application.

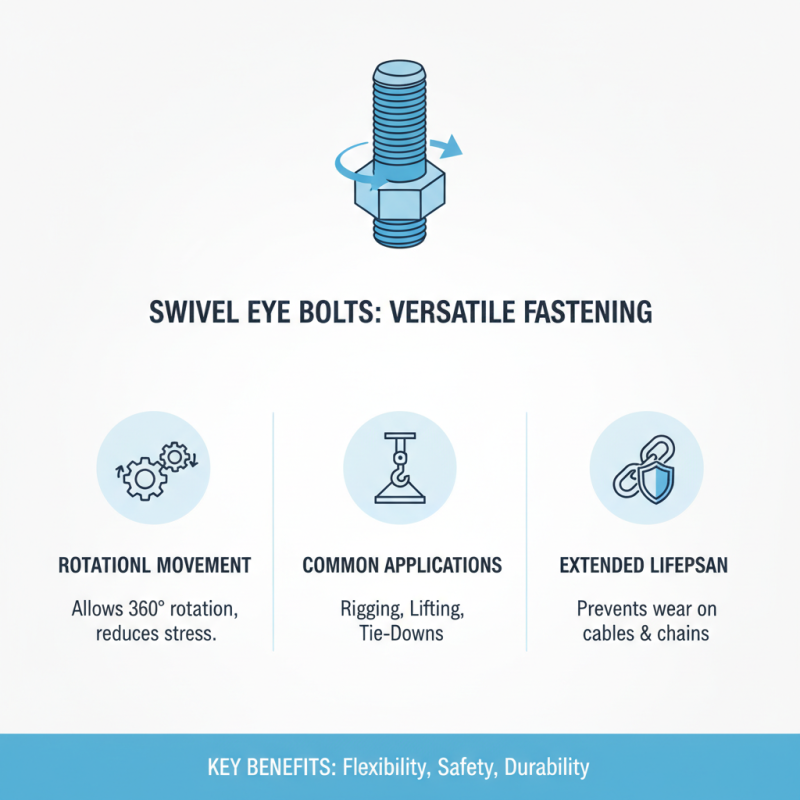

Swivel eye bolts are critical components in various rigging and lifting applications. Their unique design allows for rotational movement, which helps to reduce stress and tangling in ropes and chains. The basic components of a swivel eye bolt include the eye, the bolt, and the swivel mechanism. The eye is designed for attaching hooks or cables, while the bolt secures the assembly to structures. The swivel enables smooth movement, crucial during load adjustments.

Proper installation and maintenance of swivel eye bolts are vital. According to the National Association of Manufacturers, improper use can lead to accidents, with lift failures accounting for 29% of workplace injuries. Regular inspections help identify wear and tear. Use a checklist to ensure that the bolt is intact, and the eye rotates freely. Remember, a dysfunctional bolt can lead to costly damages.

Tips: Always match the bolt's size to the load requirements. This choice is crucial for safety and effectiveness. Overloading a swivel eye bolt can create unexpected failures. A good rule of thumb is to choose a bolt with a higher load capacity than necessary. Keep in mind that environmental factors, like rust or corrosion, can affect performance. Regularly assess these impacts.

| Component | Description | Material | Typical Uses |

|---|---|---|---|

| Eye | Holds the bolt in place and allows for rotation | Steel | Lifting, rigging applications |

| Screw Thread | Provides a means to attach the bolt to a structure | Stainless Steel | Hanging signs, equipment support |

| Swivel Joint | Allows for multi-directional movement | Bronze | Marine applications, pulleys |

| Nut | Secures the bolt in place | Steel | General fastening |

Swivel eye bolts are versatile fastening tools. They allow for rotational movement, making them useful in various applications. Commonly, they are used in rigging and lifting operations. Their unique design helps reduce stress on cables and chains, preventing wear.

In construction, swivel eye bolts aid in securing cables. They help in lifting heavy materials without tangling. In marine applications, these bolts play a crucial role in securing sails and equipment. Their ability to pivot means they adjust naturally to changing angles.

However, proper installation is vital. Inadequate tightening can lead to failures, causing accidents. Regular inspections ensure safety and functionality. These small, yet significant tools need thoughtful consideration in usage.

When it comes to installing swivel eye bolts, proper guidelines are essential for safety and effectiveness. Begin by selecting a suitable location. Make sure the surface can support the load. A weak foundation can lead to accidents. Always check the load specifications before installation. This ensures that the bolt will handle the weight it is intended for.

Next, drill a hole for the swivel eye bolt. The hole must match the diameter of the bolt. Use a drill bit designed for the material. Once the hole is ready, insert the bolt with the eye portion facing the right direction. It’s important to secure it tightly, but be careful not to overtighten. This can cause the bolt to strip or weaken.

After installation, inspect the swivel eye bolt regularly. Look for signs of wear or corrosion. A neglected bolt can fail under stress. Test the swivel mechanism by moving it gently. It should rotate freely. Any resistance might indicate a problem. While these guidelines are helpful, individual situations can vary. Always trust your instincts when assessing your setup.

Swivel eye bolts are versatile hardware components, commonly used in rigging and lifting applications. They allow for multi-directional movement, making them ideal for various tasks. However, their use comes with specific safety considerations that should not be overlooked.

When using swivel eye bolts, ensure they are correctly rated for your intended load. Inspect them regularly for signs of wear or damage. Corroded or weakened bolts can lead to accidents. It’s crucial to follow manufacturer guidelines for installation and load limits. A misplaced bolt can result in failure during operation. Tension and angle matter here; avoid angles greater than 30 degrees.

Always use the appropriate safety equipment when working with swivel eye bolts. Employ harnesses or helmets when lifting heavy loads overhead. Additionally, consider the environment. Wind or rain can affect stability. Allow time for checks before proceeding with operations. Acknowledgment and caution are essential in preventing accidents. This responsibility cannot be taken lightly. Balancing safety and functionality is key.