Rigging slings play a crucial role in lifting and moving heavy objects safely. These tools are essential in construction, shipping, and manufacturing industries. "An efficient rigging sling can mean the difference between safety and catastrophe," says John Smith, a seasoned rigging expert with over two decades in the industry. His words reflect the importance of understanding rigging slings.

Various types of rigging slings are available, including wire rope, chain, and synthetic slings. Each type serves different needs, and selection is key. Improper use can lead to severe accidents. It's crucial to inspect slings regularly. Many overlook this step, risking safety.

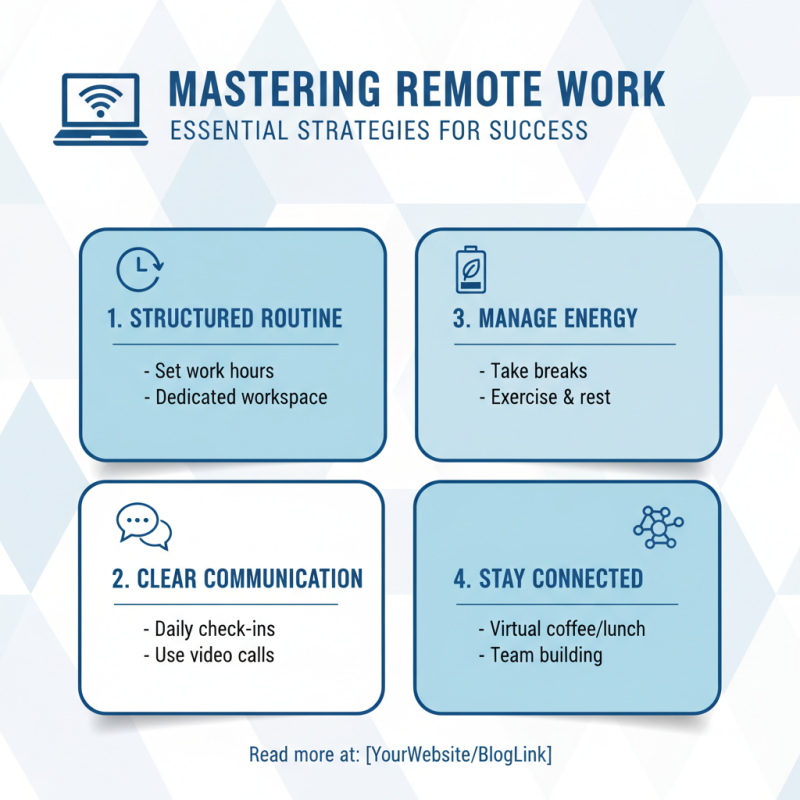

Considering the wide range of applications, knowledge about rigging slings is vital. Professionals must stay informed. Training and awareness are necessary for safe operations. While many workers have basic skills, mistakes still occur. Continuous education is essential to enhance awareness. Balancing efficiency with safety is often challenging, but it's a vital aspect of rigging slings.

Rigging slings are essential tools in the lifting and moving of heavy objects. They are made from strong materials like nylon, polyester, and wire rope. Each type has its own use and strength rating. For example, synthetic slings are lightweight and easier to handle. On the other hand, wire rope slings offer durability for heavy loads.

These slings work by connecting the load to a lifting device, like a crane. The design of the sling allows it to bear the weight safely. It’s crucial to select the right type for the job. A poorly chosen sling can lead to accidents. Regular inspection is necessary for safety too. Look for fraying, corrosion, or signs of wear. These details may seem minor, but they are vital.

Remember, using rigging slings requires training and awareness. Lifting tasks may seem straightforward, yet they involve risks. Always consult with trained professionals. Too often, people underestimate this aspect. Safety should never be compromised. Taking shortcuts is a recipe for disaster.

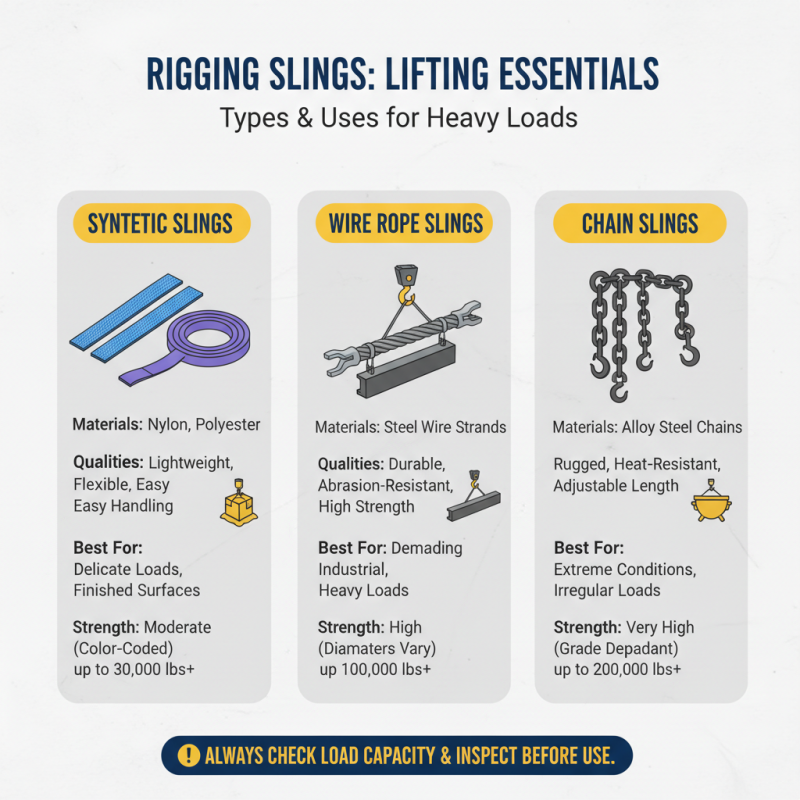

Rigging slings are essential tools in lifting and moving heavy loads. They come in various types, each suited for specific tasks. The significant types include synthetic slings, wire rope slings, and chain slings.

Synthetic slings are lightweight and versatile. They are made of materials like nylon and polyester. These materials offer excellent resistance to abrasion and UV rays. According to a recent industry report, synthetic slings can lift loads ranging from a few hundred pounds to over 20,000 pounds. They excel in applications where load protection is crucial.

Wire rope slings are known for their durability. They provide high strength and stability, making them ideal for heavy-duty lifting. However, they can rust if not maintained properly. Regular inspections are vital to ensure safety.

Chain slings stand out for their resilience and flexibility. They are used in environments with extreme temperatures or hazardous conditions. While chain slings can handle heavy weights, they may require additional care. They can become damaged through wear and abuse over time.

Tips: Always choose the right sling type for your load. Inspect slings before use. Proper handling extends their life. Remember, using the wrong sling can lead to accidents. Stay safe.

Rigging slings are essential tools in various industries, from construction to maritime. These slings help lift and move heavy objects safely. A recent report from the Industrial Lifting Equipment Association noted that improper use of slings accounts for nearly 25% of lifting accidents. This highlights the need for training and careful planning.

In construction, rigging slings are vital for hoisting beams and materials. A study by the National Safety Council showed that 80% of construction site injuries relate to lifting operations. The report emphasized the importance of using the correct type of sling. Steel slings can support extremely heavy weights, while synthetic slings are lighter and easier to handle. However, using the wrong sling can lead to disastrous results.

The maritime sector heavily relies on rigging slings for cargo handling. According to a report by the International Maritime Organization, improper rigging can stall operations and lead to costly delays. Ships must be loaded and unloaded efficiently. Sling failure can jeopardize safety. Workers need to check slings regularly and ensure they meet safety standards. Many times, slings show signs of wear but are still used. This mindset can be dangerous.

When using rigging slings, safety is paramount. Injuries related to improper use can hinder operations and put lives at risk. According to the U.S. Occupational Safety and Health Administration (OSHA), lifting incidents account for over 20% of workplace injuries. This emphasizes the importance of adhering to safety protocols.

Proper inspection is crucial before every use. Rigging slings can wear down over time. This leads to compromised strength. A study highlighted that slings with visible cuts or frays often fail at less than half their rated capacity. Users should also consider the weight of the load. Overloading slings is a common mistake, risking sudden failure and injury.

Training is essential in mitigating risks. Workers should understand how to choose the right sling for each job. Many incidents occur due to misunderstandings about load distributions. Regular safety audits can help identify areas for improvement. They also reinforce a culture of safety among team members. Remember, proper usage and awareness can prevent avoidable mishaps in rigging operations.

| Slings Type | Material | Working Load Limit (WLL) | Common Applications | Safety Considerations |

|---|---|---|---|---|

| Chain Slings | Steel | 2,500 lbs | Heavy lifting, construction | Check for wear and elongation |

| Wire Rope Slings | Steel | 5,000 lbs | Industrial rigging, towing | Inspect for kinks and corrosion |

| Synthetic Slings | Nylon or Polyester | 3,200 lbs | Lifting delicate items, aerospace | Avoid exposure to UV light |

| Round Slings | Polyester | 2,200 lbs | Transporting loads in tight spaces | Inspect for abrasions before use |

Proper maintenance and inspection of rigging slings are critical for safety. Regular checks can prevent accidents. Inspect slings for wear and tear before each use. Look for frays, cuts, or discoloration. These signs indicate potential failure points. A simple visual inspection helps identify these issues.

Cleaning is also important. Remove any debris that may compromise the sling. Dirt and grime can hide serious damage. If slings are used in harsh environments, they need more frequent inspections. Store slings properly when not in use. Avoid exposing them to extreme temperatures or direct sunlight.

Many people overlook maintenance schedules. This can lead to serious consequences. If a sling fails during use, the results can be catastrophic. Keeping a log of inspections and maintenance activities is essential. It helps track the condition over time. Slings deserve attention, and we should not take them for granted. Regular maintenance is a small effort for a significant safety gain.