Rigging chains are vital components in lifting operations across various industries. These chains offer strength and reliability, making them ideal for heavy loads. Often made from high-quality steel, they can withstand immense pressure. However, the misuse of rigging chains can lead to accidents.

In construction and shipping, rigging chains ensure safety while moving materials. Proper use is crucial to prevent failures. Operators must inspect chains before every use, looking for signs of wear and tear. This step is sometimes overlooked, resulting in potentially dangerous situations.

Understanding how rigging chains work is essential. They connect the load with lifting machinery, enabling efficient and safe operations. Yet, the lack of training can cause mistakes. Rigging chains are powerful tools, but they demand respect and caution.

A rigging chain is a heavy-duty chain designed for lifting operations. It is used in various industries, including construction and shipping. Made from high-strength steel, a rigging chain provides durability and reliability for lifting heavy loads. The links are typically welded for extra security. This design allows the chain to handle significant weight without giving way.

During lifting operations, the rigging chain connects the load to the lifting device. It can be used with hoists or cranes. The proper use of rigging chains is vital for safety. Incorrect usage can lead to accidents or equipment failures. Sometimes, operators may overlook the need for regular inspections. This can lead to deteriorated chains being used unknowingly.

Rigging chains come in various lengths and thicknesses. Choosing the correct chain for the job is crucial. Operators must consider the weight of the load and the working conditions. Overloading a chain can cause it to break or bend. Working in adverse conditions, like extreme temperatures, can also affect performance. Attention to detail in these aspects is essential for safe lifting operations.

| Dimension | Description | Usage Example |

|---|---|---|

| Material | High-strength steel | Used for heavy lifting where high tensile strength is required. |

| Load Capacity | Varies depending on chain size and grade | Can range from 1000 lbs to over 500,000 lbs for industrial rigs. |

| Chain Size | Measured in diameter (e.g., 1/4", 3/8", 1/2") | Essential for selecting the right chain for the lifting equipment. |

| Grade | Indicates the strength of the chain (e.g., Grade 30, Grade 80) | Grade 80 is commonly used for overhead lifting applications. |

| Applications | Construction, shipping, manufacturing, mining | Used in cranes, hoists, and other lifting equipment. |

A rigging chain is essential in lifting operations. Its components play a vital role in ensuring safety and efficiency. The main components include the chain links, shackles, and hooks. Each link is designed to distribute the load evenly. The strength of the links is crucial for heavy lifting.

Shackles connect the chain to the load. They come in different shapes. Some are designed for quick releases, while others provide secure attachments. Hooks are also key components. They allow for easy connection and disconnection of loads. A hook should always be inspected for wear or deformation.

The rigging chain needs to be maintained properly. Regular checks can prevent accidents. Sometimes, operators find worn chains hard to notice. This highlights the importance of routine inspections. Reflecting on the entire lifting process ensures higher safety standards. Using a steel chain may seem straightforward, but every detail counts.

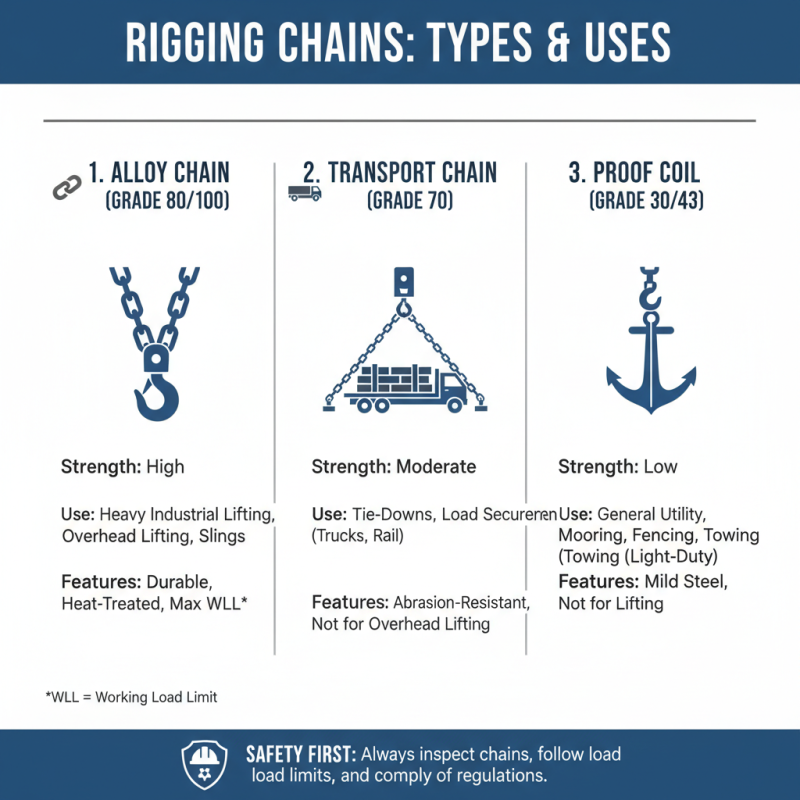

Rigging chains play a crucial role in lifting operations across various industries. These chains are designed to lift and move heavy loads safely. Understanding the types of rigging chains is essential for effective operations.

One common type is the Grade 80 chain. It has a high tensile strength and can handle heavy loads. Reports indicate that it can support loads up to five times its weight. This makes it ideal for heavy machinery. Another type is the Grade 100 chain. It has even greater strength and is often used in more demanding applications. Some data shows that it can support loads up to six times its weight.

However, challenges exist. Users must ensure proper maintenance to prevent wear and tear. Regular inspections can uncover issues like corrosion. Chains that are not maintained risk breaking during operations. Industry statistics suggest that nearly 30% of rigging accidents stem from equipment failure. Proper training for operators is also critical. Without it, mistakes can happen, leading to accidents. Regular training refreshers can help mitigate these risks.

Rigging chains are vital in various industries. They play a crucial role in lifting heavy objects safely. In construction, rigging chains hold beams and equipment during assembly. Workers rely on these chains for support and stability. Choosing the right rigging chain can be challenging. Each task has specific load requirements. Miscalculating these loads can lead to accidents.

In manufacturing, rigging chains help transport materials. They can lift heavy components onto assembly lines. With precise handling, efficiency increases. Yet, improper use of rigging chains may cause delays. It's essential to regularly inspect the chains for wear and tear. Any signs of damage should be addressed immediately.

Transport industries also utilize rigging chains. They secure loads on trucks and ships. Adequate fastening is necessary to ensure safety. However, inadequate training can result in mishandling. Ensuring proper use is crucial for avoiding injuries. Continuous education on rigging chain techniques is vital for workers across all fields.

When using rigging chains in lifting operations, safety is paramount. According to industry reports, 65% of lifting accidents stem from improper equipment use. To mitigate these risks, operators should conduct regular inspections of rigging chains. Look for cracks, rust, or deformation. Chains that show signs of wear must be replaced immediately.

In addition to routine checks, proper training is essential for all personnel. Only trained workers should operate heavy lifting equipment. Miscommunication can lead to dangerous scenarios. Always use clear signals and verify the load weight before lifting. Remember, lifting more than the chain's rated capacity is a common mistake.

Tips: Always keep a safety zone. Maintain a distance from the load while lifting. This helps prevent injuries.

Chains should be properly sized for the load being lifted. Overestimating the load’s weight can lead to failed lifts. Regular refreshers on safety protocols can eliminate many preventable errors. Lastly, document all inspections and training sessions. This creates accountability and ensures everyone is on the same page regarding safety practices.