Lifting chains with hooks are essential tools in various industries, providing a reliable means to lift and transport heavy loads safely. These chains are designed to work in conjunction with hoists, cranes, and other lifting devices, facilitating the efficient handling of materials in construction sites, warehouses, and manufacturing facilities. Understanding the different types of lifting chains with hooks and their specific applications is crucial for ensuring safety and efficiency in any lifting operation.

Choosing the right lifting chain with hooks requires careful consideration of several factors, including load capacity, material, and environmental conditions. Various hook designs, such as swivel hooks and safety hooks, offer unique benefits that can enhance both functionality and safety. By assessing the specific needs of your lifting tasks and understanding the different options available, you can select the most appropriate lifting chains with hooks for your operations. This guide will provide valuable insights into these versatile lifting solutions, helping you make informed decisions for your lifting needs.

Lifting chains with hooks are essential tools used in various industrial and construction applications, designed to facilitate the safe lifting and movement of heavy loads. These chains are constructed from high-strength steel and feature hooks at their ends, allowing for quick attachment to lifting devices such as cranes or hoists. According to a report by Grand View Research, the global lifting equipment market is expected to reach $90 billion by 2027, underscoring the growing demand for reliable lifting solutions in various sectors.

When considering the types of lifting chains with hooks, it’s essential to understand the different grades and configurations available. Common grades include Grade 30, Grade 43, and Grade 80, each offering varying levels of strength and durability. For instance, Grade 80 chains are popularly used in overhead lifting applications due to their high tensile strength and resistance to wear, making them suitable for heavy-duty operations. The choice of lifting chain should also be influenced by the nature of the load, the environment where it is used, and compliance with safety standards, such as those set by OSHA and ANSI. Proper selection of the lifting chain not only enhances operational efficiency but also significantly mitigates the risk of workplace accidents.

Lifting chains equipped with hooks are essential tools in various industries, known for their ability to safely lift and transport heavy loads. When selecting the right lifting chain, two crucial specifications to consider are load capacity and material. The load capacity indicates the maximum weight a chain can handle without risking failure, and it often varies based on the chain’s design and material composition. Generally, chains are rated based on standards such as ASME B30.9, which provides guidelines on the minimum design factors for different applications. For instance, a typical proof tested grade 80 chain can have a load capacity up to 10 tons, making it suitable for many heavy-duty tasks.

The material of the lifting chain significantly affects both its strength and durability. Chains are commonly made from alloy steels which enhance their resistance to wear and fatigue, thereby extending their lifespan. According to a report by the International Organization for Standardization, chains made of high-quality materials can exhibit tensile strengths of up to 1000 MPa, ensuring reliability under strenuous conditions. Additionally, selecting the appropriate material is vital in environments where corrosion might be a concern; for such scenarios, stainless steel or specially coated chains may be more suitable. Understanding these specifications allows users to make informed decisions, ensuring safety and efficiency in lifting operations.

When selecting lifting chains with hooks, the type of hook plays a crucial role in ensuring safety and efficiency in various applications. There are several types of hooks, each designed for specific tasks. The most common types are the slip hooks, grab hooks, and latch hooks. Slip hooks allow for quick attachment and release of the load, making them ideal for tasks that require frequent adjustments. Grab hooks, on the other hand, provide a secure grip on the chains, which is particularly beneficial when lifting heavy loads. Latch hooks add an additional layer of security, as they feature a spring-loaded latch that prevents accidental unhooking.

Understanding the application is key to choosing the right hook. For overhead lifting situations, a hook that secures the load effectively is paramount. In environments where there might be a risk of load shifting, opt for grab hooks or latch hooks to enhance stability. Moreover, consider factors such as the weight capacity and material compatibility of the hook with the load being lifted. By taking these aspects into account, one can ensure that the lifting chains not only function optimally but also promote a safer working environment.

When selecting lifting chains with hooks, one of the most important considerations is compliance with safety standards and regulations. In many industries, lifting chains are subject to strict guidelines aimed at ensuring safe operation and minimizing the risk of accidents. These standards may vary by country but often include specifications for materials, load capacity, testing procedures, and design features that enhance safety. For instance, chains must be made from high-quality steel and designed to handle specific weight loads without exceeding their limits.

To choose a lifting chain that meets safety requirements, it is crucial to consult industry regulations such as those set by organizations like the Occupational Safety and Health Administration (OSHA) or the American National Standards Institute (ANSI). These regulations often dictate the minimum safety factors that must be used and the regular inspections that should be performed to ensure the lifting equipment remains in safe working condition. Additionally, users should pay attention to markings and certifications on the chains themselves, as these can provide assurance of compliance with relevant safety standards. By adhering to these regulations, organizations can safeguard their employees and prevent costly accidents or equipment failures.

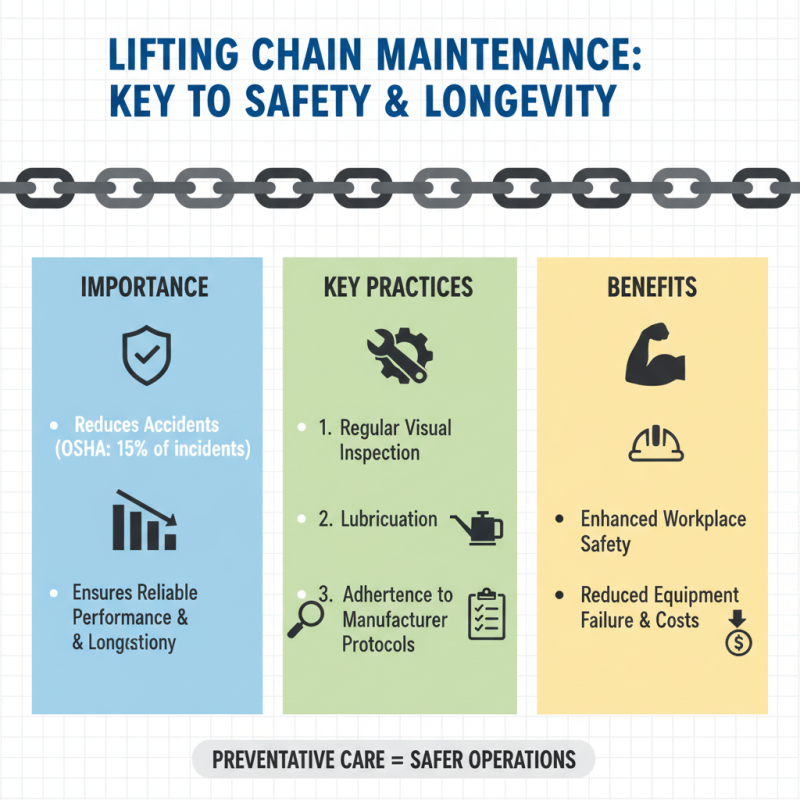

Proper maintenance of lifting chains is crucial for ensuring their longevity and reliable performance in various applications. According to a report by the Occupational Safety and Health Administration (OSHA), improper maintenance is one of the leading causes of equipment failure in the lifting industry, contributing to nearly 15% of all workplace accidents related to lifting operations. Regular inspection and adherence to maintenance protocols can significantly reduce the risk of malfunctions and enhance safety.

To maximize the lifespan of lifting chains equipped with hooks, it's essential to have a routine maintenance schedule that includes thorough inspections for wear and tear, rust, and deformation. A study published in the Journal of Loss Prevention in the Process Industries noted that chains that are cleaned and lubricated regularly can extend operational life by up to 30%. Additionally, using appropriate cleaning solutions tailored for lifting equipment, and ensuring that chains are stored in a dry and protected environment, can prevent corrosion and other forms of damage.

Employing best practices during operation also contributes to the longevity of lifting chains. It's important to avoid overloading beyond the manufacturer's specifications, as this can lead to stress fractures and premature failure. The lifting capacity should be calculated and continuously monitored, aligning with the safety factors recommended in industry standards. By combining regular maintenance with careful operational practices, businesses can ensure their lifting chains remain safe and functional for extended periods.