When undertaking any construction or industrial project, selecting the appropriate steel cable is paramount to ensuring safety and structural integrity. According to a report by the International Cable Association, the global demand for steel cables is projected to grow by 5% annually, reflecting their critical role in supporting infrastructure development. As industry expert Dr. John Smith has noted, "Choosing the right steel cable is not just about strength or flexibility; it is about understanding the specific requirements of your application." This insight underscores the necessity of informed decision-making in steel cable procurement.

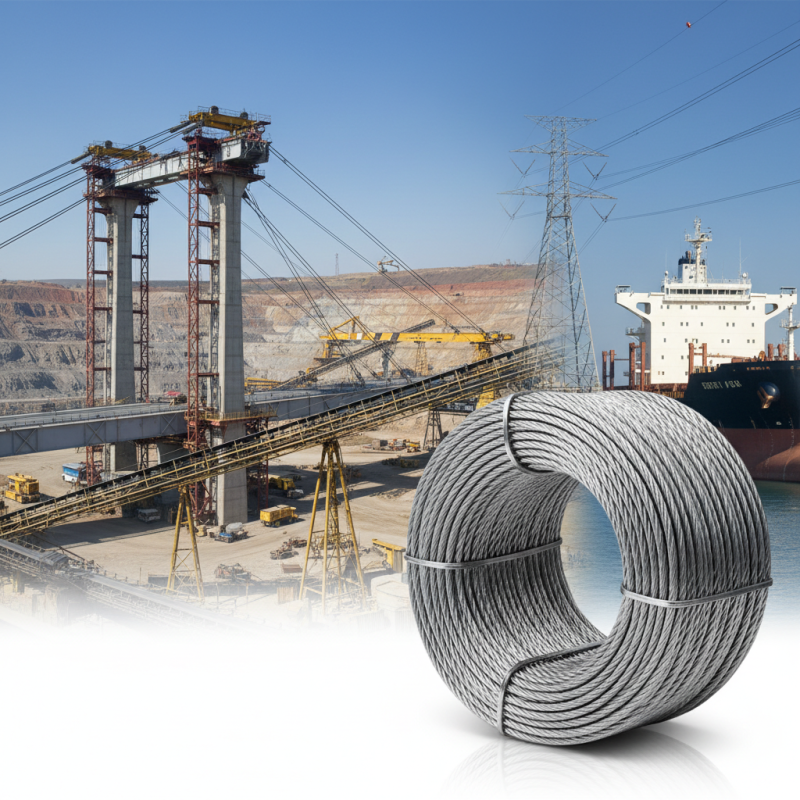

Steel cables are utilized across various sectors, from construction and mining to utilities and maritime applications. Given their diverse uses, the selection process can be complex and requires careful consideration of several key factors, including tensile strength, corrosion resistance, and the environment in which the cable will operate. The Steel Cable Manufacturers Association emphasizes that a properly chosen cable not only enhances performance but also significantly reduces maintenance costs and potential safety hazards over time. Thus, gaining a thorough understanding of each aspect related to steel cables is essential for any professional looking to optimize their project outcomes.

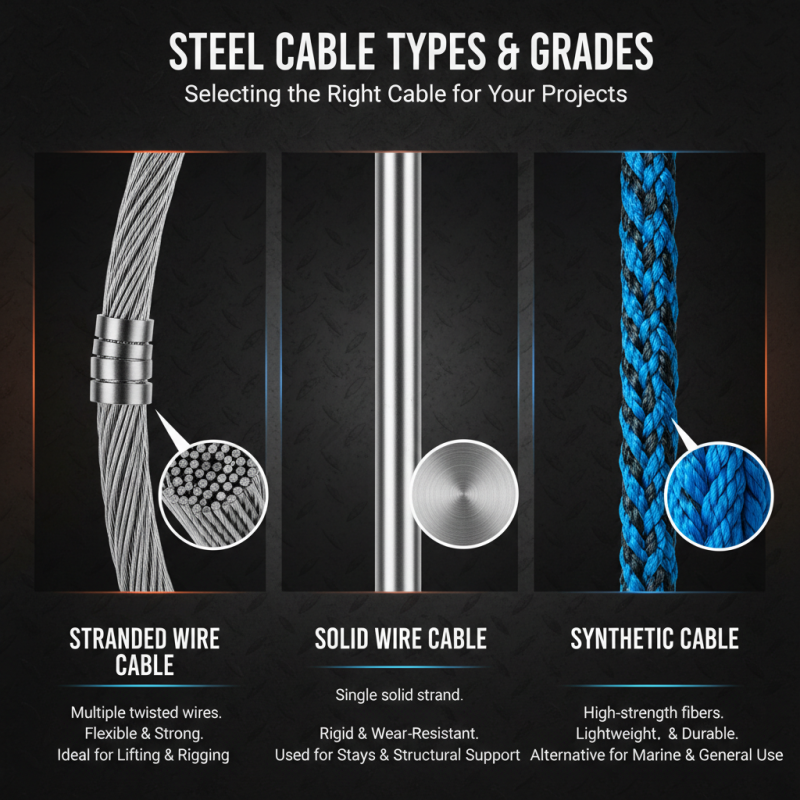

When selecting the right steel cable for your projects, it's crucial to understand the various types and grades available. Steel cables are generally categorized based on their construction, which includes stranded wire, solid wire, and synthetic options. Stranded wire cables are composed of multiple twisted wires, providing flexibility and strength, making them ideal for applications such as lifting and rigging. Solid wire cables, on the other hand, consist of a single strand and are often used in applications requiring more rigidity and resistance to wear.

Additionally, different grades of steel cables denote their strength, durability, and appropriate uses. For instance, galvanized steel cables are treated to resist corrosion, while stainless steel options offer superior resistance in harsh environments. Furthermore, the cable's diameter plays a significant role in its load capacity—larger diameters generally support heavier loads, but factors like the cable's construction and materials must also be considered. Understanding these basics will help in making informed decisions that align with the specific requirements of your projects, ensuring safety and efficiency.

When embarking on a project that requires the use of steel cables, evaluating the load capacity is crucial to ensure safety and effectiveness. Load capacity refers to the maximum weight that a cable can support under specific conditions and is vital for selecting the appropriate cable for your needs. According to the American Society for Testing and Materials (ASTM), it is recommended to choose a cable with a safety factor of at least 5:1, meaning that the maximum load should not exceed one-fifth of the cable’s breaking strength.

When determining the right steel cable, consider the type of load it will carry. For static loads, such as when cables are used in construction or rigging, ensuring that the cable can withstand not just the weight but also any additional forces, such as wind or dynamic loads, is essential. For example, a cable rated for a tensile strength of 10,000 pounds will be suitable for projects requiring less than 2,000 pounds of working load. Always reference industry data reports that provide details on cable specifications, as these can help in understanding the different characteristics of steel cables.

Additionally, factors such as environmental conditions and cable construction should not be overlooked. Certain environments may require cables with additional coatings to resist corrosion, while cable designs such as seven-strand or wire rope may provide different levels of flexibility and strength. When selecting the right cable, be sure to assess these factors closely to maintain the integrity and safety of your project.

When selecting the right steel cable for projects, understanding the environmental factors that influence durability is crucial. Studies indicate that exposure to harsh conditions, such as high humidity, extreme temperatures, and corrosive environments, significantly impacts the lifespan of steel cables. For instance, according to data from the Steel Cable Association, cables exposed regularly to marine environments can suffer a degradation rate as high as 25% over a decade due to saltwater corrosion, which necessitates the use of specially coated or galvanized cables.

Additionally, UV radiation can weaken the integrity of the steel cable over time. Research shows that cables left exposed to direct sunlight for extended periods can lose critical tensile strength, which can be quantified as a reduction of up to 15% in tensile strength after ten years of exposure. Implementing protective measures such as UV-resistant coatings can mitigate these risks, extending the service life of the cable. It's essential for project managers to consider these environmental stressors when choosing steel cables to ensure optimal performance and longevity.

| Tip | Description | Environmental Factor | Durability Rating |

|---|---|---|---|

| Corrosion Resistance | Choose cables with coatings that protect against rust and corrosion. | High Humidity | 4/5 |

| Temperature Tolerance | Select cables rated for the temperature ranges of your project environment. | Extreme Heat/Cold | 5/5 |

| UV Resistance | Ensure cables are UV-resistant if exposed to sunlight. | Outdoor Exposure | 3/5 |

| Load Capacity | Evaluate the maximum load the cable can handle based on project needs. | Dynamic Loads | 5/5 |

| Safety Standards | Check for compliance with local and international safety standards. | Regulatory Environment | 5/5 |

| Flexibility | Consider the cable's flexibility for applications requiring bending or twisting. | Tight Space Requirements | 4/5 |

| Environmental Impact | Assess the environmental impact of cable production and disposal. | Sustainability Concerns | 3/5 |

| Maintenance Requirements | Choose cables that require minimal maintenance for long-term use. | Access and Maintenance Environment | 4/5 |

| Installation Method | Select cables compatible with your installation techniques. | Installation Conditions | 4/5 |

| Cost Efficiency | Analyze the cost per unit length versus the durability offered. | Budget Constraints | 3/5 |

When selecting steel cables for various projects, it's crucial not only to focus on the cables themselves but also on the accessories and fittings that will ensure their optimal performance. Accessories such as clamps, thimbles, and connectors play a significant role in maintaining the integrity and safety of the entire rigging system. According to a recent report by the International Wire and Cable Association (IWCA), improper fittings can lead to up to 30% of failures in cable applications, emphasizing the need for quality accessories that match the specifications of your steel cable.

Choosing the right accessories involves understanding the load requirements and environmental conditions of your project. For instance, stainless steel fittings are preferred for marine applications due to their corrosion resistance, while galvanized fittings may be more suitable for industrial settings. The American Society of Mechanical Engineers (ASME) highlights that ensuring compatibility between cable and fittings is essential for achieving the desired load capacities and safety margins. Selecting the correct size and type of fittings will not only enhance the performance of your steel cable but will also contribute to the overall safety and reliability of your projects.

When it comes to maintaining the longevity of your steel cable installations, routine inspections and proper care are vital. According to a recent industry report by the International Cable Alliance, neglecting maintenance can reduce the lifespan of steel cables by as much as 50%. To avoid premature replacement and ensure optimal performance, following these essential maintenance tips is crucial.

Regularly check for signs of wear, such as fraying or corrosion. It is recommended to conduct thorough inspections every three to six months, depending on environmental exposure and usage conditions. If you notice any deterioration, it may be time to replace the cable or at least assess the situation more closely. Additionally, using protective coatings or lubricants can significantly enhance the rust resistance of steel cables, prolonging their life. Studies show that applying a protective layer can increase the overall durability of steel cables by up to 30%.

Another key aspect of maintenance is proper storage. When cables are not in use, store them in a cool, dry place, away from direct sunlight and harsh chemicals. This helps prevent environmental degradation. Additionally, ensuring that cables are not subjected to sharp bends or excessive tension when being stored will help maintain their structural integrity. By being proactive in these areas, you can prolong the lifespan of your steel cable installations and ensure they remain safe and efficient for your projects.