When it comes to lifting and moving heavy loads, chain hoists are invaluable tools that offer strength and reliability. However, with a plethora of options available in the market, selecting the right chain hoist for your specific needs can be a daunting task. Whether you are a professional in construction, manufacturing, or any industry requiring heavy lifting, understanding the various aspects of chain hoists is crucial to ensure optimal performance and safety.

In this article, we present ten essential tips to guide you through the selection process of chain hoists. From considering the load capacity and height requirements to evaluating the type of drive mechanism, each factor plays a critical role in identifying the most suitable hoist for your applications. Additionally, we will discuss maintenance considerations, safety features, and compliance with industry standards, empowering you to make informed decisions that align with your operational requirements. By the end of this guide, you will have the knowledge necessary to choose the perfect chain hoist that meets your lifting needs and enhances your workflow efficiency.

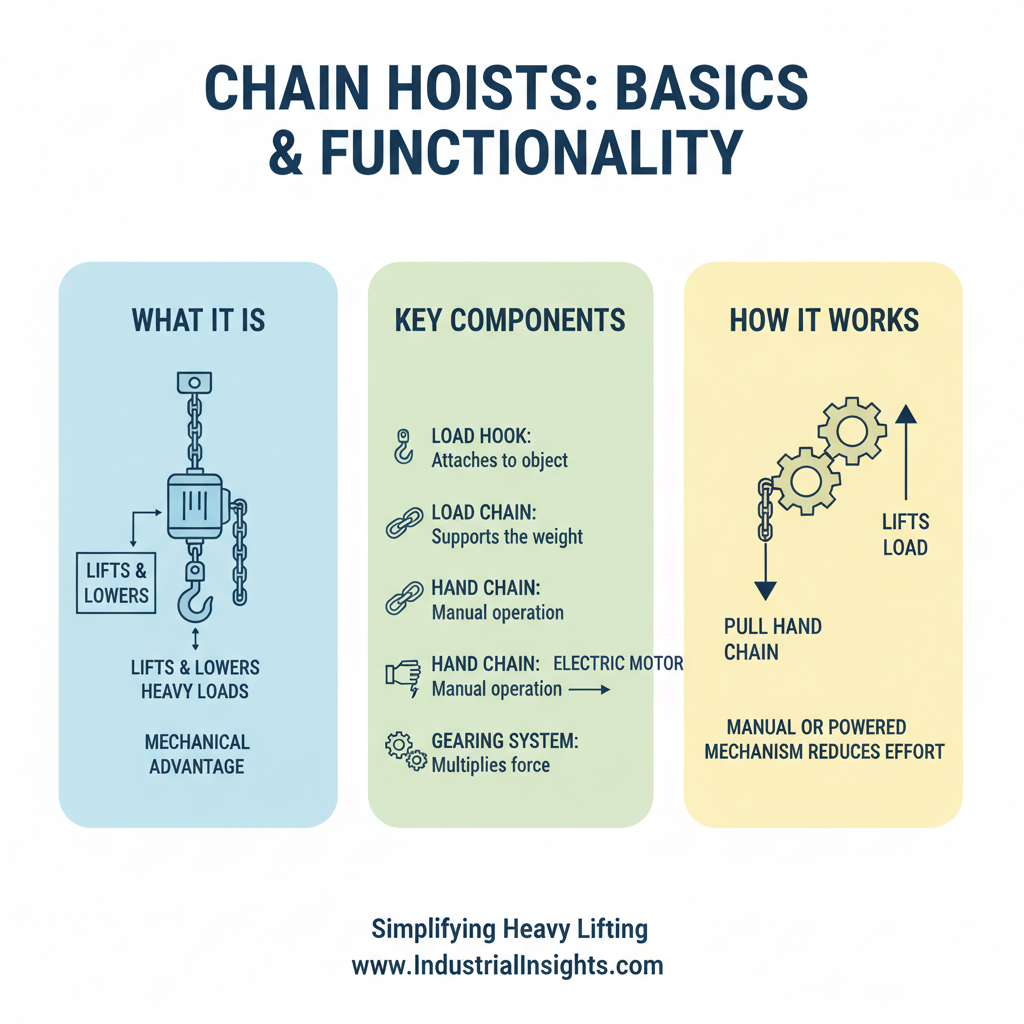

Understanding the Basics of Chain Hoists and Their Functionality

Chain hoists are essential tools in various industrial applications, designed to lift heavy loads with efficiency and safety.

These devices utilize a chain and gear system to amplify force, allowing for the movement of items that can weigh several tons.

According to a report by the Material Handling Industry of America (MHIA), the global market for hoists is projected to reach

$4.6 billion by 2025, highlighting their importance in sectors such as construction, manufacturing, and warehousing.

When choosing the right chain hoist for your needs, consider the load capacity as one of the most critical factors.

Ensure that the hoist can handle not just the maximum weight you plan to lift, but also any additional forces that may occur during operation.

Another essential tip is to evaluate the lifting speed and design. A faster hoist can increase productivity,

but it’s vital to balance speed with safety and control. Opt for hoists that comply with safety standards, such as the ASME B30.16, to minimize risks.

Lastly, think about the environment where the hoist will be used. Different settings may require specific features, such as

corrosion resistance for outdoor use or explosion-proof designs for hazardous areas.

Research from the Occupational Safety and Health Administration (OSHA) indicates that improper lifting applications account for

20% of workplace injuries, emphasizing the need for choosing the right equipment.

Carefully considering these factors can significantly enhance operational efficiency and safety in your lifting tasks.

When selecting a chain hoist for specific tasks, it is crucial to consider several key factors to ensure optimal performance and safety. One essential aspect is the load capacity; understanding the weight of the items you intend to lift is vital. According to industry standards, an adequate safety margin should be included, typically a minimum of 25%, to protect against overload situations. Furthermore, the type of material—be it steel, aluminum, or synthetic—can significantly influence the durability and weight of the hoist, tailoring it to the operational environment.

Another critical factor is the intended use of the chain hoist. Different tasks may require varying features, such as single versus double falls, speeds of operation, or portability. Market reports indicate that the integration of advanced technology—like AI-driven automation in supply chain management—enhances the efficiency of such tools. With rapid advancements in automation, investing in a hoist that aligns with these innovations can boost productivity.

For instance, modern chain hoists are often designed with user-friendly controls, allowing for better operator interaction in increasingly automated environments, ensuring a seamless workflow while mitigating potential risks associated with manual handling.

When selecting the right chain hoist, evaluating load capacity and safety ratings is paramount to ensuring efficiency and safety in your operations. First, determine the weight of the loads you typically handle. It's essential to choose a chain hoist that exceeds your maximum load requirements. A hoist with a load capacity of at least 125-150% of your maximum weight provides an essential safety margin, helping to prevent mechanical failures during operation.

Additionally, pay attention to the safety ratings of the chain hoist. Look for hoists that comply with recognized safety standards, such as those set by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). These certifications indicate that the hoist is tested for durability and safety, thus ensuring that it can withstand the rigors of heavy-duty lifting.

Incorporating these tips into your selection process will result in a more reliable and practical hoist for your needs. Always consult user reviews and seek recommendations from industry professionals to enhance your understanding of different models and their performance. This proactive approach will aid in making a more informed decision while prioritizing safety and reliability in your operations.

When it comes to selecting the right chain hoist for your needs, one of the key decisions is choosing between manual and electric options. Manual chain hoists are often favored for their simplicity and cost-effectiveness. They require no electricity, making them ideal for outdoor use or locations without power sources. Users have complete control over the lifting speed and can maintain a high level of precision, which is crucial for delicate loads. However, manual hoists can be physically demanding, particularly for heavy lifting, and they may not be the best choice for frequent or repetitive tasks.

On the other hand, electric chain hoists offer significant advantages in terms of speed and efficiency. They can lift heavier loads with less physical effort, making them suitable for industrial environments where productivity is a priority. Electric hoists come equipped with safety features such as overload protection and limit switches, enhancing user safety during operations. However, they require access to power and can be more expensive both in terms of initial investment and maintenance. Ultimately, the choice between manual and electric chain hoists should be based on your specific applications, load requirements, and working conditions.

| Feature | Manual Chain Hoists | Electric Chain Hoists |

|---|---|---|

| Operation | Manual operation via hand chain | Powered operation using electric motor |

| Weight Capacity | Varies, typically up to 5 tons | Varies, typically up to 20 tons |

| Speed of Operation | Slower, dependent on operator | Faster, consistent speed provided by motor |

| Maintenance | Low maintenance | Requires regular electrical maintenance |

| Portability | Highly portable | Less portable, dependent on power source |

| Cost | Generally lower cost | Generally higher cost |

| Usage Scenarios | Ideal for light to moderate lifting tasks | Ideal for heavy lifting and repetitive tasks |

| Safety Features | Basic safety features | Advanced safety features like overload protection |

| Operator Training | Minimal training required | Training on electrical safety may be required |

| Environmental Considerations | Works without electricity, useful in remote areas | Dependent on electrical infrastructure |

When investing in a chain hoist, maintenance and care are crucial for ensuring longevity and optimal performance. Regular inspections are essential; according to industry data, approximately 50% of hoist failures can be traced back to inadequate maintenance protocols. Operators should routinely check components, including chains, hooks, and gears, for wear and tear. In addition, lubrication of moving parts is vital; it not only reduces friction but also protects against corrosion. A well-maintained chain hoist can last up to 10 years longer than one that is neglected, substantially increasing return on investment.

Moreover, proper storage can significantly extend the lifespan of your chain hoist. It is recommended to store hoists in a dry, clean environment to prevent rust and corrosion. According to studies by the Material Handling Industry, hoists that are frequently exposed to harsh environments can experience a reduction in lifespan by as much as 30%. Additionally, training staff on proper handling techniques can prevent misuse, which is a common cause of premature failure. Adhering to a rigorous maintenance schedule and ensuring proper care will not only enhance safety but also maximize efficiency in your operations.