In the world of lifting and rigging, choosing the right materials can significantly impact safety and efficiency. Steel rope, renowned for its superior strength and durability, has become a preferred choice for many professionals in the industry. John Smith, a leading expert in lifting and rigging solutions, asserts, "Steel rope is not just a practical choice; it's an investment in safety and reliability." This statement encapsulates the sentiment shared by countless industry veterans who recognize the pivotal role steel rope plays in ensuring secure and efficient operations.

As industries evolve and the demands for lifting solutions increase, the need for robust materials like steel rope becomes even more pronounced. Its ability to withstand high tensile loads, resist abrasion, and endure harsh environments makes it indispensable for various applications ranging from construction sites to maritime operations. This introduction to the importance of steel rope sets the stage for a deeper exploration of its benefits and the reasons it stands out as a top choice for lifting and rigging needs. Whether it’s for heavy-duty lifting or intricate rigging setups, the versatility of steel rope proves its worth time and again.

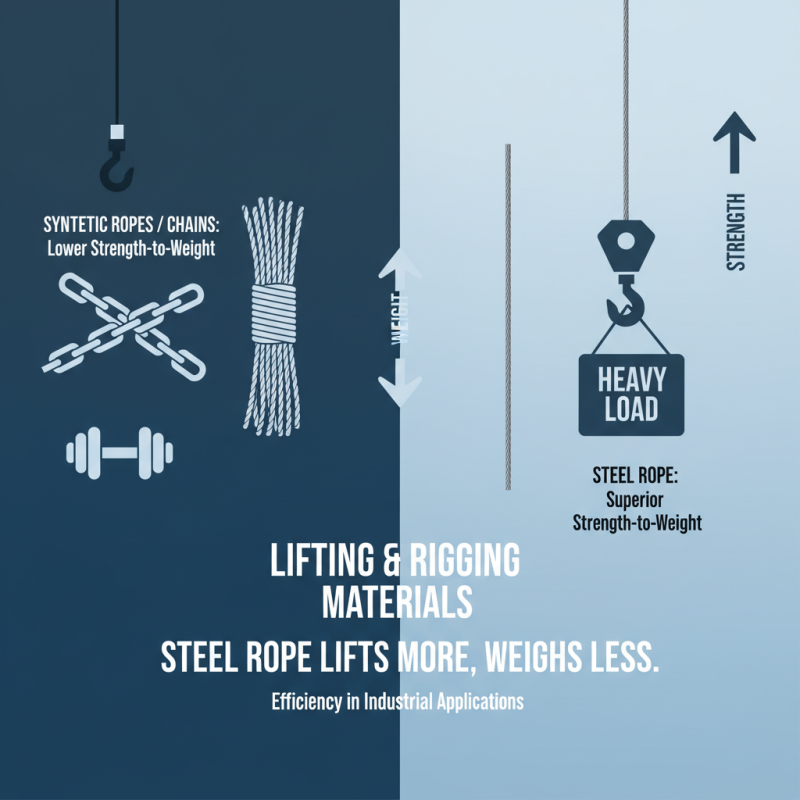

Steel rope, also known as wire rope, offers numerous advantages for lifting applications, making it a preferred choice for many industries. One of the primary benefits of steel rope is its exceptional strength-to-weight ratio. This characteristic allows for significant lifting capabilities without adding unnecessary weight to the overall rigging setup. Additionally, steel rope is highly resistant to wear and corrosion, ensuring longevity and reliability even in harsh environments. This durability reduces the need for frequent replacements, lowering maintenance costs over time.

When utilizing steel rope, safety should always be a priority. Tip: Regularly inspect your steel ropes for any signs of fraying or damage. This proactive approach can prevent failures during critical lifting operations. Furthermore, it’s important to choose the right diameter and construction type of steel rope for your specific lifting needs, as these factors can greatly impact performance and safety.

Another notable benefit of steel rope in lifting applications is its flexibility. Unlike other materials, steel rope can be easily spooled and managed, which greatly enhances maneuverability on job sites. Tip: Use appropriate reels or storage solutions to keep the ropes tangle-free and in optimal condition. Taking these steps can significantly enhance operational efficiency and ensure the longevity of your lifting equipment.

When it comes to lifting and rigging applications, the choice of material plays a crucial role in ensuring both safety and efficacy. Steel rope stands out as the superior option, primarily due to its unmatched durability and strength. Unlike synthetic materials that may degrade over time or lose their integrity when exposed to various environmental factors, steel maintains its performance under extreme conditions such as high temperatures, harsh weather, and heavy loads. This resilience is essential in industries like construction, shipping, and manufacturing, where equipment must withstand rigorous daily demands.

In addition to its durability, steel rope's strength-to-weight ratio significantly enhances its practicality for lifting operations. It offers a remarkable capacity for withstanding tension without extensive elongation, thereby ensuring that loads remain stable and secure during transit. The tensile strength of steel rope enables it to handle larger weights compared to other materials, making it an invaluable asset for heavy-duty tasks. Furthermore, the ability to operate effectively under dynamic loads, where forces can fluctuate, adds another layer of reliability that is crucial in preventing accidents and ensuring operational efficiency.

| Property | Steel Rope | Synthetic Rope | Natural Fiber Rope |

|---|---|---|---|

| Tensile Strength (MPa) | 400-600 | 200-400 | 100-300 |

| Weight (kg per 100 meters) | 20-30 | 5-10 | 30-50 |

| Abrasion Resistance | High | Moderate | Low |

| UV Resistance | Fair | Excellent | Poor |

| Longevity | 30+ years | 10-20 years | 5-10 years |

When considering lifting and rigging needs, weight plays a crucial role in determining the best material for the job. Steel rope offers a significant advantage over alternative materials such as synthetic ropes or chains when it comes to weight-to-strength ratio. Steel ropes are known for their high tensile strength, allowing them to support heavier loads without the bulk associated with other options. This strength enables more efficient lifting operations, which can be particularly beneficial in industrial applications where maximum load capacity is essential.

Moreover, steel ropes exhibit minimal stretch compared to their synthetic counterparts, which often means they can operate more effectively under high stress. The reduced elasticity not only enhances precision in lifting but also helps maintain load stability throughout the process. This characteristic is particularly important in scenarios where control and safety are paramount. In contrast, alternative materials may introduce a level of unpredictability due to stretching, making steel rope a more reliable choice for heavy lifting and rigging tasks. Therefore, for projects demanding a careful balance of weight considerations and strength, steel rope remains the preferred selection.

When it comes to lifting and rigging operations, safety is paramount.

Steel rope has gained popularity due to its robust construction and superior strength, making it a reliable choice for various industrial applications. One of the most significant safety features of steel rope is its high tensile strength, which reduces the risk of rope failure during heavy lifting tasks. This inherent strength allows for secure handling of loads without the fear of sudden breaks, providing peace of mind to operators.

Additionally, steel ropes are often designed with fatigue resistance and minimal stretch. This means they can endure repeated loads over long periods without losing their structural integrity, which is crucial in environments where consistent performance is required. The lower elasticity also translates to better control during operation, allowing for more precise lifting and lowering of loads.

Tip: Always inspect steel ropes for visible signs of wear or damage before every use. Look for fraying, kinking, or corrosion, as these can significantly compromise safety.

Another key aspect of steel ropes is their versatility in design. They can be coated or treated to enhance performance, providing better grip and reducing the likelihood of slippage during operations. Utilizing proper rigging techniques alongside high-quality steel ropes ensures a safer working environment.

Tip: When selecting steel rope for rigging, consider the specific requirements of your operation, including load weight and environmental conditions, to choose the most suitable rope type.

When considering lifting and rigging operations, the long-term cost-effectiveness of steel rope becomes a key factor in decision-making. Steel ropes, made from high-tensile materials, offer exceptional durability and strength, allowing them to withstand heavy loads and extreme conditions. Unlike synthetic alternatives, steel ropes maintain their structural integrity over time, reducing the frequency of replacements and minimizing downtime in operations. This resilience translates to significant cost savings, as businesses can avoid the expenses associated with regular replacements and repairs.

Moreover, the longevity of steel ropes adds an additional layer of value. While the initial investment might be higher compared to other materials, the extended lifespan of steel ropes ensures that they provide a better return on investment over time. Their resistance to wear and tear means fewer disruptions in the workflow, which can be crucial in industries where efficiency is paramount. Companies can rest assured that their investment in steel ropes will support their operational needs for years, thereby justifying the upfront costs with long-term savings and enhanced reliability.