In the evolving landscape of construction and engineering, the choice of materials plays a critical role in the success of any project. Among these materials, stainless cable stands out due to its durability, corrosion resistance, and versatility. According to industry expert Michael Thompson, “Selecting the right stainless cable is essential for ensuring both the safety and longevity of your project.” With advancements in technology and a plethora of options available, making an informed decision can be daunting.

In this guide, we will explore the various factors to consider when choosing stainless cable for your specific needs. From understanding the different grades of stainless steel to evaluating the strength and flexibility required for your project, each decision influences the overall quality and performance. With an emphasis on practicality and functionality, we aim to equip you with the knowledge necessary to make the best choice for your upcoming projects, ensuring that your use of stainless cable not only meets expectations but exceeds them.

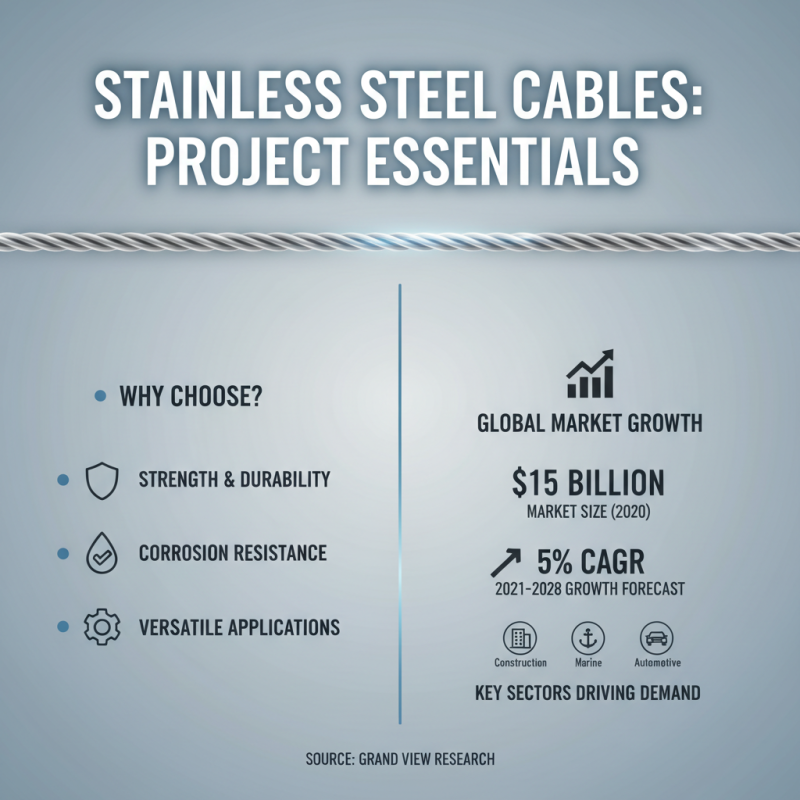

When selecting the right stainless steel cable for your project, understanding the basics of stainless steel cables is crucial. Stainless steel cables are ubiquitous in various applications due to their strength, resistance to corrosion, and overall durability. According to a report by Grand View Research, the global stainless steel wire market size was valued at approximately $15 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of around 5% from 2021 to 2028. This highlights the increasing demand for stainless steel products in construction, marine, and automotive sectors.

One of the fundamental aspects to consider is the type of stainless steel used—most commonly, 304 and 316 grades. While 304 stainless steel is suitable for general use and offers decent corrosion resistance, 316 grade is often preferred in marine environments due to its superior resistance to salt and chlorides. According to the International Stainless Steel Forum, the properties of these grades significantly affect the cable's performance, leading to distinct applications based on environmental conditions. For anyone undertaking a project that requires stainless steel cables, a thorough understanding of these different grades and their properties is essential for ensuring optimal performance and longevity.

When choosing the right stainless steel cable for your projects, it’s vital to identify the key applications that best utilize the unique properties of these cables. Stainless steel cables are renowned for their strength, corrosion resistance, and versatility, making them an ideal choice for various applications such as marine, architectural, and industrial uses. According to a report by Smithers Pira, the demand for stainless steel cables in construction and infrastructure is expected to grow at a CAGR of 5% from 2023 to 2028. This highlights the increasing reliance on durable materials in these sectors, driven by the need for sustainable and long-lasting solutions.

To select the appropriate stainless steel cable, consider the specific requirements of your application, including load capacity, environmental exposure, and required flexibility. For example, cables used in marine environments should feature higher corrosion resistance, often achieved with *316-grade stainless steel*. On the other hand, architectural projects may prioritize aesthetic aspects along with strength. Tip: Always verify the tensile strength and compatibility of the cable with other components in your project to ensure safety and performance.

Furthermore, understanding the installation and maintenance needs of stainless steel cables can significantly impact their longevity and effectiveness. Regular inspections and proper installation techniques are key factors in ensuring optimal performance in any application. Tip: Consider using protective coatings or lubricants to enhance corrosion resistance and reduce wear, especially in high-stress or abrasive environments. By following these insights, project managers can make informed decisions that lead to successful outcomes.

When selecting the right stainless cable for your projects, understanding the different grades of stainless steel is crucial for ensuring durability and long-lasting performance. Stainless steel is categorized into various grades, each with distinct properties and applications. Grades such as 304 and 316 are commonly used; 304 stainless steel offers good corrosion resistance and is suitable for indoor applications, while 316 provides added resistance against saltwater and harsher environments, making it ideal for marine applications. According to the International Stainless Steel Forum (ISSF), nearly 70% of stainless steel production is of the 304 and 316 grades, reflecting their widespread use in various industries.

Durability often hinges on the specific environmental factors the stainless cable will encounter. For instance, exposure to chlorides, humidity, and temperature variations can significantly influence the performance of the material. A report by the American Society of Mechanical Engineers (ASME) suggests that the use of lower-grade stainless steels in harsh environments can lead to pitting corrosion, thereby reducing the lifespan and functionality of the cable. Thus, for projects exposed to demanding conditions, investing in higher-grade stainless steel, such as 316 or even specialty grades like 2205 duplex stainless steel, can provide the necessary durability and cost-effectiveness over time.

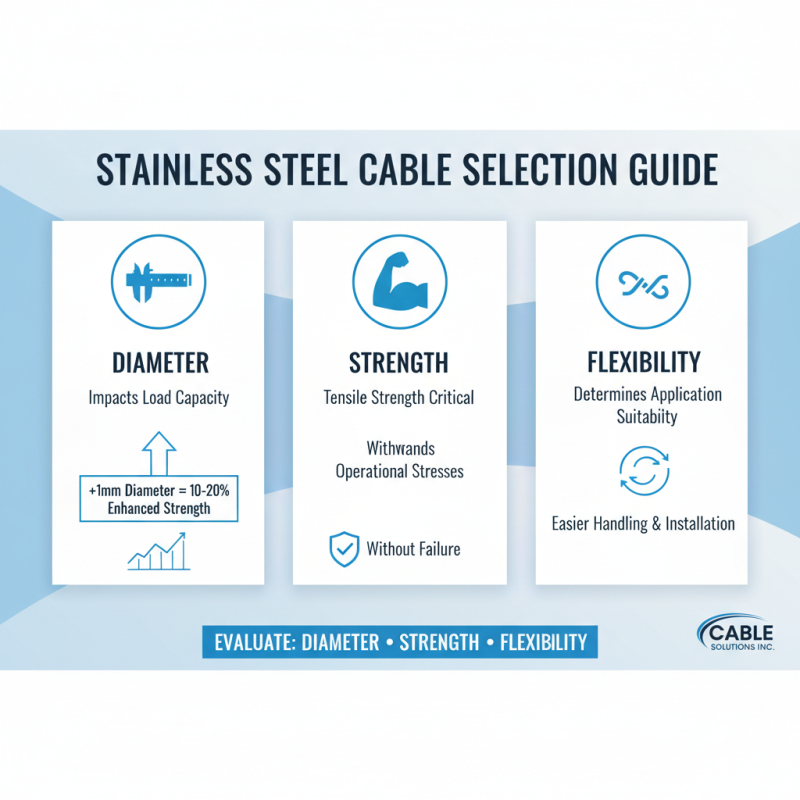

When selecting the right stainless cable for your projects, crucial specifications such as diameter, strength, and flexibility must be thoroughly evaluated. The diameter of the cable directly impacts its load-bearing capacity. According to a recent industry report, cables with a diameter increase of just 1 mm can enhance tensile strength significantly, often by 10-20%. This is critical for applications requiring specific load requirements, ensuring the cable can withstand operational stresses without failure.

Strength is another vital factor to consider. Stainless steel cables usually exhibit a minimum breaking strength (MBS), which can vary based on the type of steel used and the cable's construction. For instance, cables made from 316 stainless steel often provide superior corrosion resistance and have a higher MBS, making them ideal for marine environments. A comprehensive understanding of these metrics is essential, as failing to choose a cable with adequate strength might lead to project failures or safety hazards.

**Tips:** When evaluating cables, always check the manufacturer's specifications for tensile strength and load ratings. Additionally, consider the flexibility of the cable, especially in applications that require intricate bends or movement. A more flexible cable can reduce wear and tear, ultimately extending its lifespan. Conducting thorough research and consulting with industry experts can also provide invaluable insights, ensuring you make an informed decision tailored to your project needs.

When working with stainless steel cables, selecting the appropriate accessories and hardware is crucial for ensuring durability, reliability, and overall project success. The key components you need to consider include cable grips, crimping ferrules, and tensioning devices. Each of these accessories plays a significant role in maintaining the integrity of your cable system. For instance, cable grips should match the diameter of your cables and be suited for the specific application, whether it’s for architectural use or load-bearing structures.

Additionally, the choice of hardware can greatly impact the performance of your stainless steel cable system. This includes selecting the right fasteners and connectors that are compatible with your cable specifications. Hardware such as turnbuckles and eye bolts must be made from high-quality materials to resist corrosion, particularly in challenging environments. Opting for hardware with a proper load rating ensures that your project can withstand the intended loads, providing peace of mind and structural safety. By focusing on the right accessories and hardware, you ensure that your stainless steel cable installations are safe, functional, and aesthetically pleasing.