When embarking on projects that require strength and reliability, the choice of materials can significantly impact both safety and efficiency. Steel wire rope has emerged as a preferred solution across various industries due to its exceptional strength-to-weight ratio and superior durability. According to a report by the International Organization for Standardization (ISO), the global steel wire rope market is projected to reach $2.78 billion by 2026, growing at a CAGR of 4.6%. This growth is attributed to the increasing demand for high-performance materials in sectors such as construction, marine, and telecommunications.

The advantages of steel wire rope extend beyond mere statistics; its design allows for considerable load-bearing capabilities while maintaining flexibility, making it suitable for a range of applications from lifting and hoisting to securing structures. The Metal Markets Research reports that steel wire ropes can withstand harsh environmental conditions, including extreme temperatures and corrosive substances, further highlighting their practical benefits. By incorporating steel wire rope into your next project, you not only ensure robustness and longevity but also align with industry standards that prioritize safety and efficiency.

Steel wire rope is a versatile and robust solution primarily used in various industrial applications, from construction to mining. Understanding the composition and types of steel wire rope can aid in making informed choices for your next project. The basic composition of steel wire rope typically includes steel wires twisted together around a core, which can be made of fibers or steel. This construction provides a high strength-to-weight ratio, contributing to the rope's load-bearing capacity and durability. According to a report by MarketsandMarkets, the global steel wire rope market is projected to reach USD 4.21 billion by 2026, demonstrating the increasing reliance on this material across industries.

Different types of steel wire ropes are available, each tailored to specific applications. For instance, multi-strand ropes, which consist of several wires twisted together, are commonly used in lifting and hoisting applications due to their excellent flexibility and resistance to wear. On the other hand, locked-coil ropes, known for their superior resistance to crushing and bending, are ideal for applications involving more significant mechanical stress. Industry research indicates that the demand for specialized steel wire ropes has surged by approximately 7.1% annually, reflecting the trend towards more advanced and durable lifting solutions in various sectors. Understanding these types allows engineers and project managers to select the best option tailored to their project's unique requirements, ensuring safety and efficiency.

Steel wire rope is known for its high strength, durability, flexibility, lower weight, and cost-effectiveness. This bar chart illustrates the key benefits of using steel wire rope in various projects, showcasing its strengths in different dimensions.

Steel wire rope offers a plethora of benefits across various applications, making it an essential choice for construction, mining, and marine industries. Its superior tensile strength, which can reach up to 1770 MPa, allows it to carry heavy loads with a minimal risk of failure. According to the International Organization for Standardization (ISO), steel wire ropes can withstand extreme conditions, making them ideal for lifts, cranes, and cable cars, where safety and reliability are paramount.

One significant advantage of steel wire rope is its resistance to abrasion and corrosion, especially when treated with anti-corrosive coatings. This feature extends the lifespan of the rope significantly; a study from the Cordage Institute indicates that properly maintained steel wire ropes can last up to 10 years longer than their synthetic counterparts in harsh environments. This durability translates into lower maintenance and replacement costs over time, enhancing overall project efficiency.

Tips: When selecting steel wire rope, always consider the specific application and load requirements. Ensure the correct diameter and construction type is chosen for optimal performance. Regular inspections for wear and damage are also crucial; establishing a routine maintenance protocol can vastly improve the lifespan of your wire rope and ensure safety on the job.

When it comes to selecting materials for heavy-duty projects, steel wire rope is often the top choice due to its remarkable durability and strength. Unlike alternatives such as nylon or polyester, steel wire rope can withstand extreme loads and harsh environmental conditions. Its unique construction allows it to resist wear and fatigue, making it an ideal solution for applications in construction, mining, and marine industries. The high tensile strength also ensures that it can handle significant weight without compromising safety.

When opting for steel wire rope, consider these tips: always evaluate the specific load requirements for your project to select the appropriate cable diameter and construction type. Additionally, regular inspection and maintenance are crucial to prolonging the lifespan of the rope. Look for signs of fraying or corrosion that could indicate potential issues before they become critical.

Another advantage of steel wire rope is its versatility. It can be easily customized to suit various applications, whether you need a flexible rope for elevation or a robust one for towing. Its inherent strength makes it suitable for both dynamic and static loads, offering peace of mind in demanding situations. By understanding the key benefits and taking proper care of your steel wire rope, you can ensure optimal performance in your future projects.

When considering materials for your next project, cost efficiency is a crucial factor that cannot be overlooked. Steel wire rope offers significant long-term savings, primarily due to its durability and strength. Unlike alternative materials, steel wire rope is designed to withstand harsh environmental conditions, including heavy loads and weather variations, which often leads to lower replacement and maintenance costs over time. The extended lifespan of steel wire rope makes it a wise investment, eliminating the frequent need for repairs or replacements that can quickly accumulate in expenses.

Additionally, the versatility of steel wire rope contributes to its cost-effective nature. It can be utilized across various applications, from construction to marine operations, which reduces the need for multiple types of materials in a single project. This flexibility not only lowers initial expenditure but also simplifies inventory management and logistics, ultimately saving time and resources. Therefore, choosing steel wire rope is not just about immediate costs; it promotes significant long-term savings through its exceptional durability and versatility, making it a smart choice for any project.

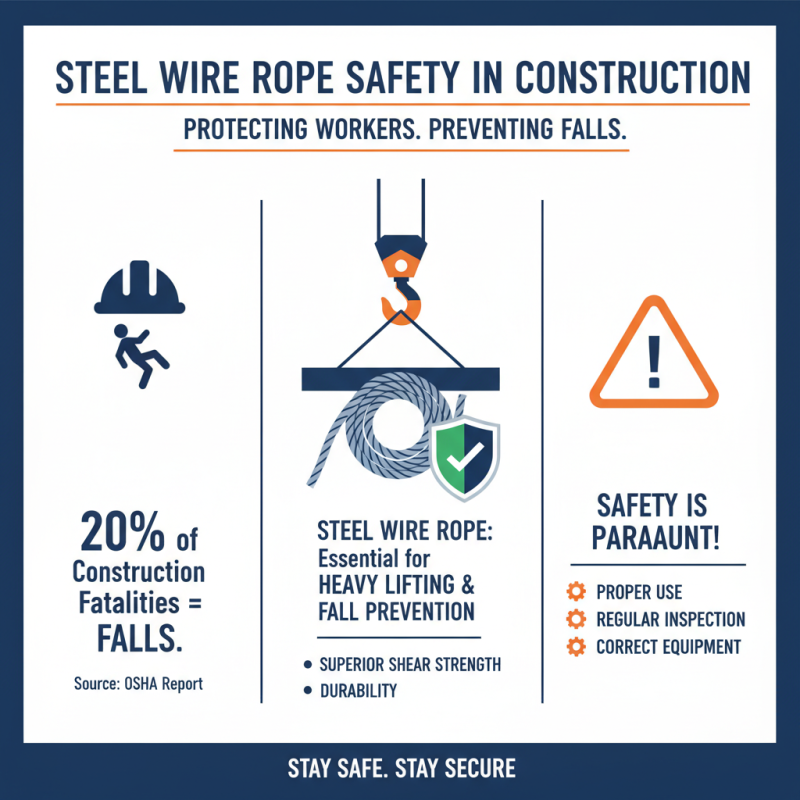

When it comes to using steel wire rope in construction and rigging projects, safety is paramount. According to a report by the Occupational Safety and Health Administration (OSHA), approximately 20% of worker fatalities in the construction industry are due to falls, which can be directly mitigated through proper safety measures and equipment such as steel wire ropes. The shear strength and durability of steel wire rope make it ideal for heavy lifting, but without appropriate safety considerations, the risks can be significant.

One important safety consideration is the need for regular inspection and maintenance of steel wire rope. A study published in the International Journal of Occupational Safety and Ergonomics highlights that nearly 30% of accidents involving lifting equipment arise from equipment failure, which often stems from wear and tear that goes unnoticed. It's crucial to check for signs of fraying, kinking, or any other damage that could compromise the integrity of the wire rope. The National Association of Amusement Ride Safety Officials suggests that having a rigorous inspection schedule, including daily checks for visible damage and annual comprehensive inspections, can greatly reduce the risk of accidents.

Moreover, understanding the correct load limits is fundamental. The wire rope's breaking strength should exceed the maximum expected load, providing a safety factor that accounts for potential overload scenarios. The American Society of Mechanical Engineers recommends a safety factor of at least five times the maximum load to ensure reliable performance. By adhering to these guidelines and employing steel wire rope correctly, project managers can significantly enhance the safety and efficacy of their operations.