In the world of industrial lifting, the choice of equipment can significantly impact both efficiency and safety. One of the most versatile tools available for lifting heavy loads is the 4 leg chain sling. According to John Smith, a leading expert in lifting technologies, "The 4 leg chain sling offers unparalleled stability and load distribution, making it essential for any heavy lifting operation." This statement highlights the fundamental advantages of utilizing a 4 leg chain sling, particularly in scenarios where balance and safety are paramount.

The design of the 4 leg chain sling allows for the lifting of bulky or awkwardly shaped loads with greater control, minimizing the risk of accidents or damages. Additionally, its ability to distribute weight evenly across multiple points reduces stress on both the sling and the load, enhancing durability and performance. In this article, we will explore the various benefits of choosing a 4 leg chain sling for your lifting needs while also providing valuable safety tips to ensure secure and efficient operations. By understanding the advantages of this equipment, professionals can make informed decisions that contribute to safer work environments.

A 4 leg chain sling is an optimal choice for lifting applications due to its superior load distribution and stability. Unlike their single or double leg counterparts, the 4 leg sling provides a higher level of support by evenly distributing the weight across four points. This not only enhances safety by reducing the risk of slippage or tipping but also allows for the lifting of larger and heavier loads with confidence. The versatility of a 4 leg chain sling makes it suitable for a variety of lifting scenarios, including construction, shipping, and manufacturing processes.

When utilizing a 4 leg chain sling, it is crucial to follow certain safety tips to ensure effective use. Firstly, always inspect the chain sling for signs of wear, such as elongation or damage, before each use. Properly attach the legs to the load, ensuring that they are aligned at appropriate angles to maximize lifting efficiency and prevent undue stress. It is also important to ensure that the load is balanced and securely slung before lifting commences. Training users in proper rigging practices can further enhance safety and operational efficiency.

Another tip to consider is the importance of calculating the load's weight accurately. Overloading a chain sling can lead to catastrophic failures, so it’s essential to ensure that the chosen sling has an adequate working load limit. Additionally, avoid sudden movements or jerking forces when lifting, as these can compromise the integrity of the sling. By adhering to these guidelines, operators can fully leverage the benefits of a 4 leg chain sling while maintaining a safe working environment.

| Benefits | Safety Tips | Applications | Load Capacity (Tons) |

|---|---|---|---|

| Increased Stability | Inspect slings before use | Construction sites | 15 |

| Versatile Adjustability | Use appropriate hardware | Manufacturing | 10 |

| Balanced Load Distribution | Ensure proper rigging angles | Shipping and logistics | 20 |

| Durability in Harsh Conditions | Avoid shock loading | Oil and gas industry | 25 |

When it comes to heavy lifting, the choice of equipment is critical, and a 4 leg chain sling stands out for its superior performance capabilities. One of the key features of these slings is their ability to distribute weight evenly across each leg. This load distribution not only reduces the risk of slippage or imbalance during lifting but also enhances stability, making them ideal for moving large and awkwardly shaped loads. The multi-leg design provides greater versatility, enabling operators to adjust angles and configurations to suit specific lifting scenarios.

Additionally, the robust construction of 4 leg chain slings, typically made from high-strength steel, ensures durability and resistance to wear and tear. This resilience is crucial in industrial environments where equipment is subjected to significant stress. Furthermore, many 4 leg chain slings come equipped with safety features such as safety latches on hooks and marked load capacities, which aid in the prevention of accidents and assure compliance with safety standards. The incorporation of these features not only bolsters operational efficiency but also significantly enhances user safety during lifting operations.

This chart illustrates the key performance metrics for 4 leg chain slings, highlighting their load capacity, safety rating, durability, versatility, and ease of use. Choosing a 4 leg chain sling can significantly enhance lifting operations due to these beneficial features.

When utilizing a 4 leg chain sling for lifting operations, safety should always be the top priority. A 4 leg chain sling provides enhanced stability for loads, but it is crucial to ensure that it is used correctly to prevent accidents. One of the primary safety considerations is to ensure the sling is rated for the weight of the load. Before lifting, double-check the weight and ensure it does not exceed the sling’s capacity. Additionally, inspect the sling for any signs of wear or damage, such as cracks or deformation in the links, which could compromise its integrity.

Tips for safe usage include ensuring that the lifting angle remains optimal. A 4 leg chain sling is designed for specific angles and exceeding these can increase stress on the sling, which might lead to failure. Always adjust the sling properly to maintain an angle between 30 and 60 degrees from the vertical position. Furthermore, ensure that all personnel involved in the lifting operation are trained in safe lifting procedures to communicate effectively and respond to any potential hazards while the lift is in progress. Regularly update training and equipment inspections to maintain safety standards during operations.

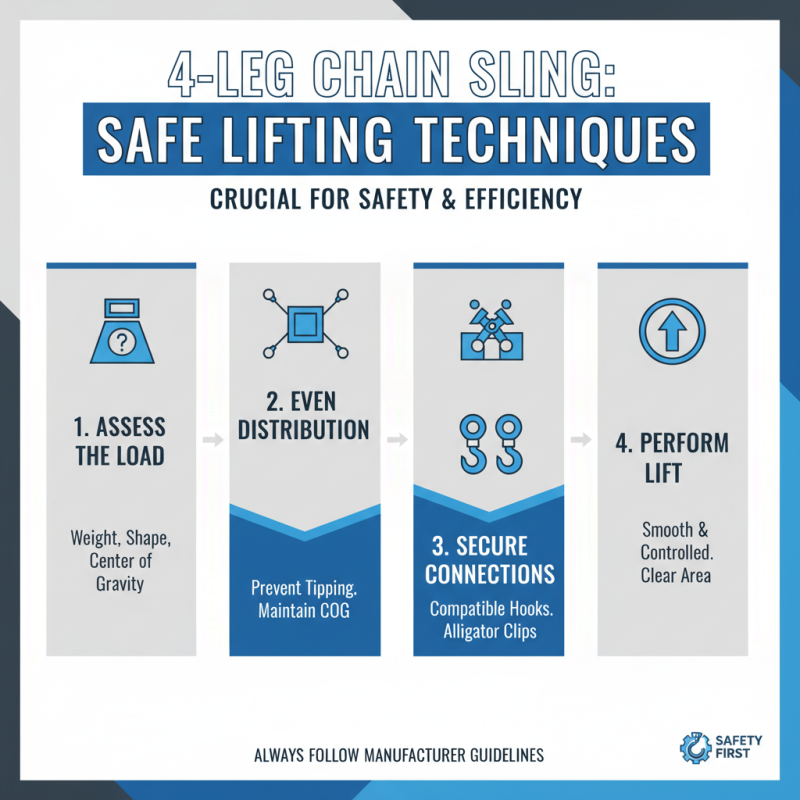

When it comes to using a 4 leg chain sling for lifting, the correct techniques for attachment and operation are crucial to ensure safety and efficiency. Properly attaching a chain sling requires that you first assess the load's weight, shape, and intended lift. Ensure that the chain legs are evenly distributed and that the center of gravity is maintained to prevent any tipping during the lift. It is important to use compatible hooks and ensure that all connections are secure before lifting.

Tips for effective attachment include inspecting the chain sling for any wear or damage prior to use. Always check that the lifting eyes or hooks are not obstructed and that they align correctly with the load. Additionally, when attaching the sling, use a tag line to help control the load while being lifted, reducing the risk of swinging or rotating.

While operating the chain sling, maintain clear communication with all team members involved in the lift. Use hand signals or radios to ensure that everyone is aware of the operation's progress. Once the load is elevated, avoid walking under the sling, and keep a safe distance while the load is in motion. Following these techniques and tips will not only enhance safety but also improve overall lifting performance.

Proper maintenance of a 4 leg chain sling is essential for maximizing its lifespan and ensuring safety during lifting operations. According to industry standards, regular inspections should be carried out on chain slings to identify signs of wear, corrosion, or deformation. The Occupational Safety and Health Administration (OSHA) recommends that these inspections occur at least annually, but more frequent checks are advisable depending on the usage intensity. Notably, 20% of sling-related accidents can be attributed to inadequate maintenance practices, highlighting the importance of vigilance in ensuring chain sling integrity.

To enhance the longevity of your chain sling, it is important to follow best practices during usage and storage. Keith Johnson of the National Association of Manufacturers indicates that improper storage can reduce the working life of lifting equipment by up to 50%. Chain slings should be stored in a dry, cool environment, away from heat sources and corrosive materials. Additionally, operators should avoid shock loading, which not only increases the risk of failure but can also lead to micro-cracking in the chain links. Regular lubrication, as specified in guidelines from industry experts, can also prevent corrosion and improve the smooth function of the sling, ensuring safe and reliable lifting operations.